Acrion Solid Surface Cutting and Cutout

Discover the process of cutting and cutout for Acrion solid surface. Learn about the tools needed, step-by-step instructions, and safety precautions to achieve a customized and professional look for your project.

Introduction

Solid surface materials are popularly used for countertops, tables, and other surfaces because of their durability and versatility in design. Acrion solid surface is a particularly high-quality solid surface material that is known for its resistance to heat, stains, and impact. But how is Acrion solid surface cut and customized to fit specific needs? In this article, we’ll explore the process of cutting and cutout for Acrion solid surface.

Tools and Equipment

*Circular saw or jigsaw

*Router

*Clamps

*Cutting blades or bits

*Sanding disks

*Dust mask and safety goggles

Cutting Process

Step 1: Prepare the Surface

Before cutting, it’s important to prepare the Acrion solid surface. This may involve cleaning the surface and ensuring that it is free of debris. It’s also important to determine the dimensions and design of the cut before starting.

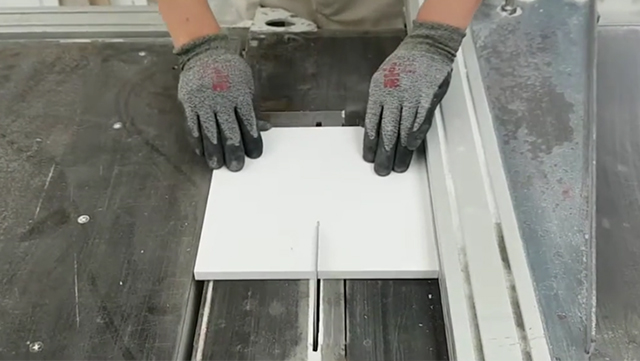

Step 2: Set Up the Equipment

Next, set up the tools and equipment for cutting. Use clamps to secure the Acrion solid surface to a stable surface, such as a workbench or sawhorse. If using a circular saw, adjust the blade to the appropriate depth for the cut.

Step 3: Make the Cut

Carefully make the cut using the appropriate tool. A circular saw may be used for straight cuts, while a jigsaw may be used for more intricate cuts. Use a router to create smooth edges or cutouts. Be sure to wear a dust mask and safety goggles to protect against debris.

Step 4: Sand the Edges

After making the cut, use sanding disks to smooth the edges of the Acrion solid surface. This will help to create a finished look and prevent any sharp edges.

Cutout Process

Step 1: Prepare the Surface

Just like with cutting, it’s important to prepare the Acrion solid surface before creating a cutout. Clean the surface and determine the dimensions and design of the cutout.

Step 2: Set Up the Equipment

Set up the tools and equipment, including clamps to secure the Acrion solid surface to a stable surface. Use a jigsaw or router to carefully create the cutout. Be sure to use the appropriate cutting blades or bits for the material.

Step 3: Sand the Edges

After creating the cutout, use sanding disks to smooth the edges. This will help to prevent any sharp edges and create a finished look.

Conclusion

Cutting and cutout for Acrion solid surface can be accomplished with the right tools and equipment. Always take safety precautions when working with power tools, and carefully plan and measure the cut or cutout before beginning. With these tips, you can achieve a customized and professional look for your Acrion solid surface project.

Technology of China

Not Just Acrylic Solid Surface, Acrion Design Ideas Inspired Endless.

What you’re searching for goes beyond ordinary solid surface solutions. You deserve a trusted collaborator with over two decades of craftsmanship, poised to address your distinctive design aspirations. Let Acrion be your compass on the path to architectural brilliance. Not Just Surfaces, Acrion Elevates Your Creations Beyond Boundaries.

ACRION IS AN OUTSTANDING ACRYLIC SOLID SURFACE SHEET MATERIAL THAT CAN BE MOULDED TO ANY SHAPE – FROM BEAUTIFUL WORKTOPS TO STUNNING FACADES.

ACRION(Learn more…) is an outstanding solid surface material. A delicate composition of acrylic, minerals and natural pigments that combine to create a smooth, non-porous, thermoformable and visually seamless surface.

The material meets the highest standards for quality in all aspects: material performance, fabrication, functionality and hygiene.

Thanks in a large part to this quality and the outstanding flexibility in fabrication and design, ACRION? offers countless advantages over conventional materials.

Official website Address:https://acrion.com.cn/